All inclusive

Research and Development

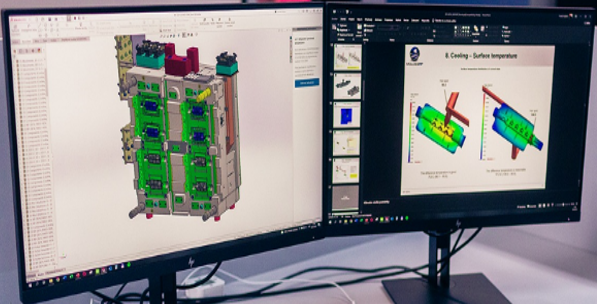

In the development phase, we work on the first designs of the parts. We run the simulations of injection process prediction from the early stage of the part´s design. The output of analysis is used for proper tool designs and process parameters set-up.

Besides the simulations, we are able to make the parts on the 3D printer in the early phase of projects. Such printed parts can be used for not only for the feasibility assessment but also as prototype parts for our customers.

Design and engineering

All design works are done in 3D environment. We use the programs Solidworks or Creo. We have ready the experienced team of people who understand their work and always find the best possible solution for either design of new IM tool or the repair/correction of existing IM tool.

After the 3D design of tool and 2D production drawings are done, there comes the engineers to make the technological preparation for the production. The technological preparation is done in the program SolidCAM.

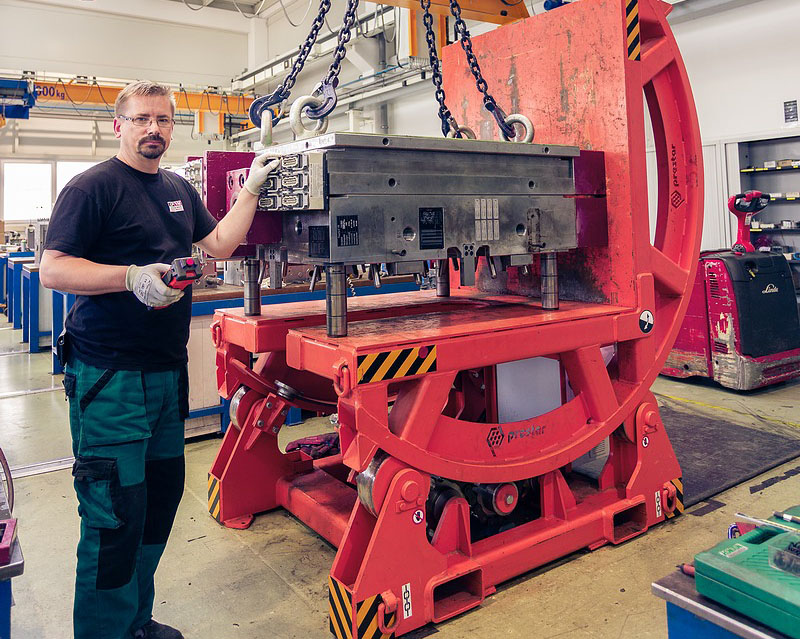

IM tool production

We produce new injection molding tools and also make the maintenance, corrections and repairs of running serial tools. In our fully equipped tool-shop, we make the production of new injection molding tools, maintenance of running serial tools and possibly also the correction of tools based on the customer requests.

Our engineers in the tool-shop work with the software Solidworks for CAM and CAD data. Our machine park includes all necessary machines like the machining centers, EDM, milling machines, grinders, wire-cutting machines, laser welding etc.

Realization

Our main scope of work is the production of plastic parts for automotive market. On the production area 4.000 m2, you can find 72 injection molding machines with the clamping force 25t-650t. Besides the injection molding, we do also the assembly, welding and tampo-printing.

We are the specialists for 2K injection molding process on both technical and also visual/optical parts. Our production is very focus on the automatization of processes (robots, controls by sensors, cams etc.).

Quality

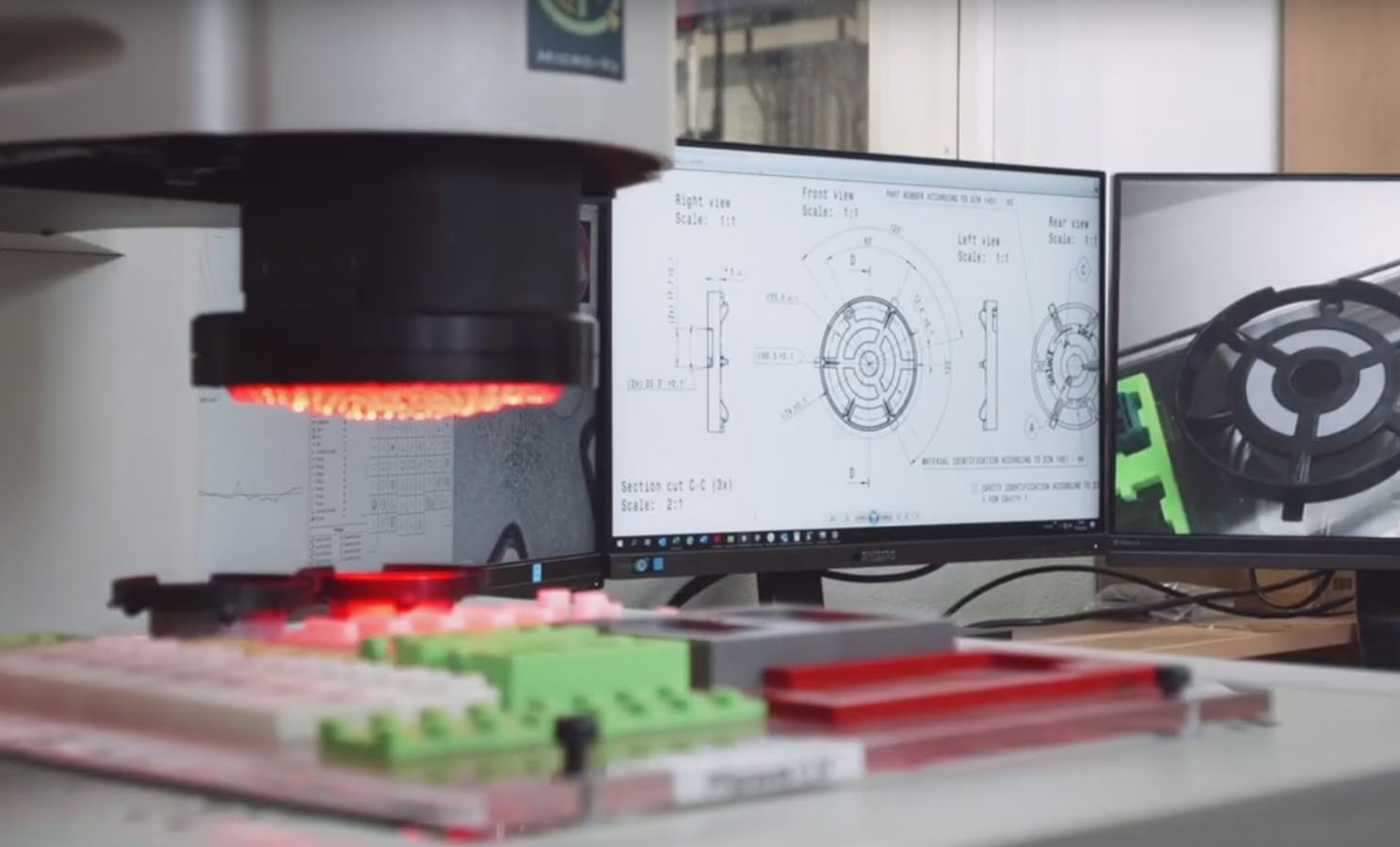

Our mindset works according to the motto: The customer shall return, not the product. We thus work in the culture of zero defect quality. Such mindset is supervised by experienced quality team who has the main task to prevent any quality issues.

For such culture must be assured the quality already in the development phases of projects by experienced project teams. From the project phase continues the quality assurance also into the serial production where we put the emphasis on the regular checks during the serial productions. For the assurance of quality, besides the important processes like FMEA, control plan, mold-flow etc., we need to have the measurement laboratory.

Our measurement laboratory has 3D CMM machines, optical measurement machine, altimeter, microscopes, spectophotometer but also the machines for the measurement of lighting characteristics for the optical parts. Besides all above mentioned internal machines, we can arrange the CT scans and other testing according to the requests from our customers.

Logistic

Logistic and storage are very important and final parts of project phases. Besides very important process to develop and produce the parts, there are also important processes to store the parts and deliver them to the customers. Our company assure the storage and deliveries according to the customer requests. It means that we are able to offer the just-in-time deliveries but also safety stocks. In our big self-automatic warehouse we have available around 6.000 storage positions.